Trimix Concrete Flooring Services

Trimix Concrete Flooring Services Specification

- Usage/Application

- Industrial Flooring, Warehouse Flooring, Commercial Flooring

- Joint Type

- Expansion/Contraction Joints provided

- Material Used

- Ready-mix Concrete, Hardener, Sealant

- Location Type

- Industrial, Commercial, Residential

- Service Duration

- As per project size

- Compressive Strength

- 25-40 MPa

- Curing Time

- 24-48 hours

- Thickness

- 50 mm to 300 mm

- Service Type

- Trimix Concrete Flooring Services

- Flooring Type

- Trimix

- Service Mode

- Offline

- Minimum Area

- 5000 Sq.ft

- Payment Mode

- Online/Offline

- Surface Finish

- Smooth, Non-slip

About Trimix Concrete Flooring Services

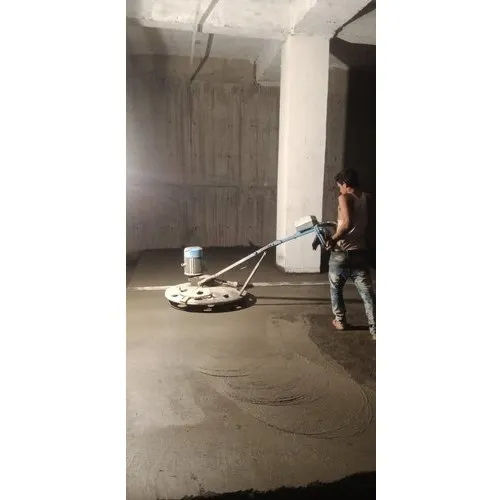

Trimix Concrete Flooring Services involve the installation and finishing of industrial or commercial concrete floors using the Trimix concrete method. This method is commonly used to achieve high-quality, durable, and flat concrete floors in various settings. Trimix concrete is compacted using mechanical vibrating screeds or pavers to ensure uniform density and surface finish. This is known for achieving high levels of flatness, making it suitable for industrial and commercial applications where level surfaces are critical. Trimix Concrete Flooring Services are chosen for their ability to provide a robust and level surface, making them suitable for a wide range of industrial and commercial applications.

Product details

|

Service Duration |

As Per Work |

|

Service Location |

Pan India |

|

Service Mode |

Offline |

|

Service Type |

Trimix Flooring |

|

Other Flooring Services |

Concrete Flooring |

|

Is It Provide AMC |

Provide Amc |

|

Service Location/City |

Pan India |

|

Provide Service In |

Commercial Building |

|

Services We Provides |

Polishing |

Engineered for Tough Environments

Trimix Concrete Flooring is designed to withstand rigorous use in demanding settings like factories, warehouses, and commercial spaces. The surface is enhanced with hardener and sealant, providing high durability and resistance to wear, chemicals, and impacts.

Precise Installation & Lasting Finish

Every project is completed by expert teams using the latest machinery. The precise application of expansion and contraction joints ensures structural integrity while maintaining a smooth, non-slip finish. The ready-mix material quickly achieves optimum strength within 48 hours.

FAQ's of Trimix Concrete Flooring Services:

Q: How is the Trimix Concrete Flooring installed and what is the process involved?

A: Trimix Concrete Flooring installation begins with surface preparation, followed by pouring ready-mix concrete. A hardener is mechanically applied, then the surface is finished using specialized equipment. Finally, a sealant is added for protection, and expansion/contraction joints are created to control cracking.Q: What benefits does Trimix Concrete Flooring offer for industrial and commercial applications?

A: This flooring type delivers superior durability, high compressive strength (25-40 MPa), and excellent resistance to abrasion and chemicals. Its non-slip, smooth finish ensures safety and efficient movement, making it ideal for industrial, warehouse, and commercial spaces.Q: When can the newly installed Trimix concrete floor be used?

A: The flooring requires a curing period of 24 to 48 hours after installation. Once cured, it achieves its optimal strength and surface finish, allowing for safe operational use in your facility.Q: Where can Trimix Concrete Flooring be applied?

A: Trimix flooring is suitable for a variety of environments including industrial, commercial, warehouse, and select residential spaces across India. It is ideal for areas requiring tough and long-lasting floors.Q: What is the minimum area required for Trimix Concrete Flooring services?

A: Service is available for projects with a minimum area of 5000 sq.ft, accommodating large industrial or commercial flooring needs.Q: How does the inclusion of expansion and contraction joints benefit the floor?

A: Expansion and contraction joints help manage concrete movement, reducing the risk of cracks and extending the lifespan of your floor, particularly in large-area or high-traffic environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS